In-Situ Geotechnical Testing

In-Situ Testing for Comprehensive Geotechnical Investigations

In-situ testing is a critical method in geotechnical investigations, enabling the measurement of key geotechnical parameters directly in the field. This minimizes soil and mine tailings disturbance while providing reliable data for engineering and construction projects. Legion Drilling offers industry-leading in-situ testing capabilities, including Cone Penetration Testing (CPT), Piezocone Testing (CPTu), Seismic Cone Penetration Testing (SCPTu), Marchetti Flat Dilatometer Testing (DMT), and Electrical Vane Shear Testing. These advanced systems are designed to deliver precise, real-time data for a wide range of geotechnical challenges.

Advantages of Legion Drilling’s In-Situ Testing Systems

Our in-situ testing methods provide numerous benefits that make them invaluable for geotechnical site investigations:

Rapid data collection: High-density geotechnical data is collected quickly, saving time and resources while improving the quality of decision-making.

Cost-effectiveness: Compared to traditional soil sampling and laboratory testing, in-situ testing is more economical while maintaining accuracy.

Real-time data visualization: Live data streams from systems like CPTu and SCPTu enable engineers to assess site conditions immediately, optimizing project workflows.

Enhanced reliability: By reducing uncertainties, in-situ testing improves confidence in geotechnical analysis and minimizes project risks.

Additionally, high-quality soil and tailings samples can be collected using direct push technology or other advanced sampling methods in adjacent locations to complement in-situ testing results.

Cone Penetration Testing (CPT) and Variants

Legion Drilling specializes in CPT, CPTu, and SCPTu, which are essential for evaluating soil stratigraphy, groundwater pressure, and seismic site characterization. These methods are ideal for assessing soft soils, mine tailings, and other challenging conditions. Our CPTu systems integrate piezometers to measure pore water pressure, while SCPTu provides seismic wave velocity profiles for dynamic soil properties.

Flat Dilatometer Testing (DMT)

The Marchetti Flat Dilatometer Test (DMT) is a versatile tool for determining soil strength, stiffness, and consolidation characteristics. DMT results help engineers design foundations, retaining structures, and earthworks with higher precision.

Electrical Vane Shear Testing

For direct assessment of undrained shear strength in cohesive soils, Legion Drilling offers Electrical Vane Shear Testing, which delivers accurate results for stability analysis in critical infrastructure projects such as dams, embankments, and tailings storage facilities.

Sonic Drilling and Geotechnical Sampling

Legion Drilling has expanded its capabilities by incorporating Sonic drilling rigs into our fleet. Sonic drilling offers highly efficient, clean, and precise sample recovery across a wide variety of soil and rock types. Combined with our in-situ testing systems, this allows us to provide comprehensive solutions tailored to each project's geotechnical requirements.

Trusted by Leading Clients in Australia

As one of the most versatile geotechnical drilling contractors in Australia, Legion Drilling is trusted by top engineering firms, mining companies, government agencies, and organizations managing critical infrastructure like dams and tailings storage facilities. Our clients rely on us for projects requiring advanced geotechnical site investigations, from government infrastructure projects to mining operations and defense installations.

Comprehensive Geotechnical Services

With cutting-edge equipment, experienced personnel, and a proven track record, Legion Drilling provides end-to-end services for geotechnical site investigations. Whether it's collecting high-quality samples, performing Cone Penetration Testing, or deploying Sonic drilling rigs, our solutions are designed to meet the most demanding geotechnical challenges.

By combining innovative technology with decades of expertise, Legion Drilling continues to set the standard for geotechnical site investigation services in Australia.

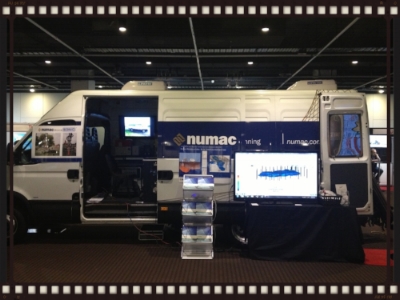

Precision geotechnical data and drilling capacity in a single machine.

Seismic CPTu (SCPTu)

Measurement of both compression and shear wave velocities (Vp, Vs) in mine tailings and soils.

Flat Dilatometer Marchetti Test (DMT)

In-situ test sensitive to soil stress history and compaction.

Electrical Vane Shear Testing

Estimation of undrained and remoulded (residual) shear strength in clay and mine tailings.

Meeting standards for equipment and methodology.

3D Visualisations

There is no more powerful way to present information to stakeholders and design cost-effective solutions.

The next presentations will be dedicated to MiHPT (Membrane-Interface & Hydraulic Profiling Tool) and UVOST (Ultra-Violet Optical Screening Tool), two direct sensing tools that have revolutionised the way we investigate contaminated sites thanks to their high resolution and real-time visualisation capabilities.