Electrical Vane Shear Testing

ESTIMATION OF UNDRAINED SHEAR STRENGTH IN CLAY AND MINE TAILINGS

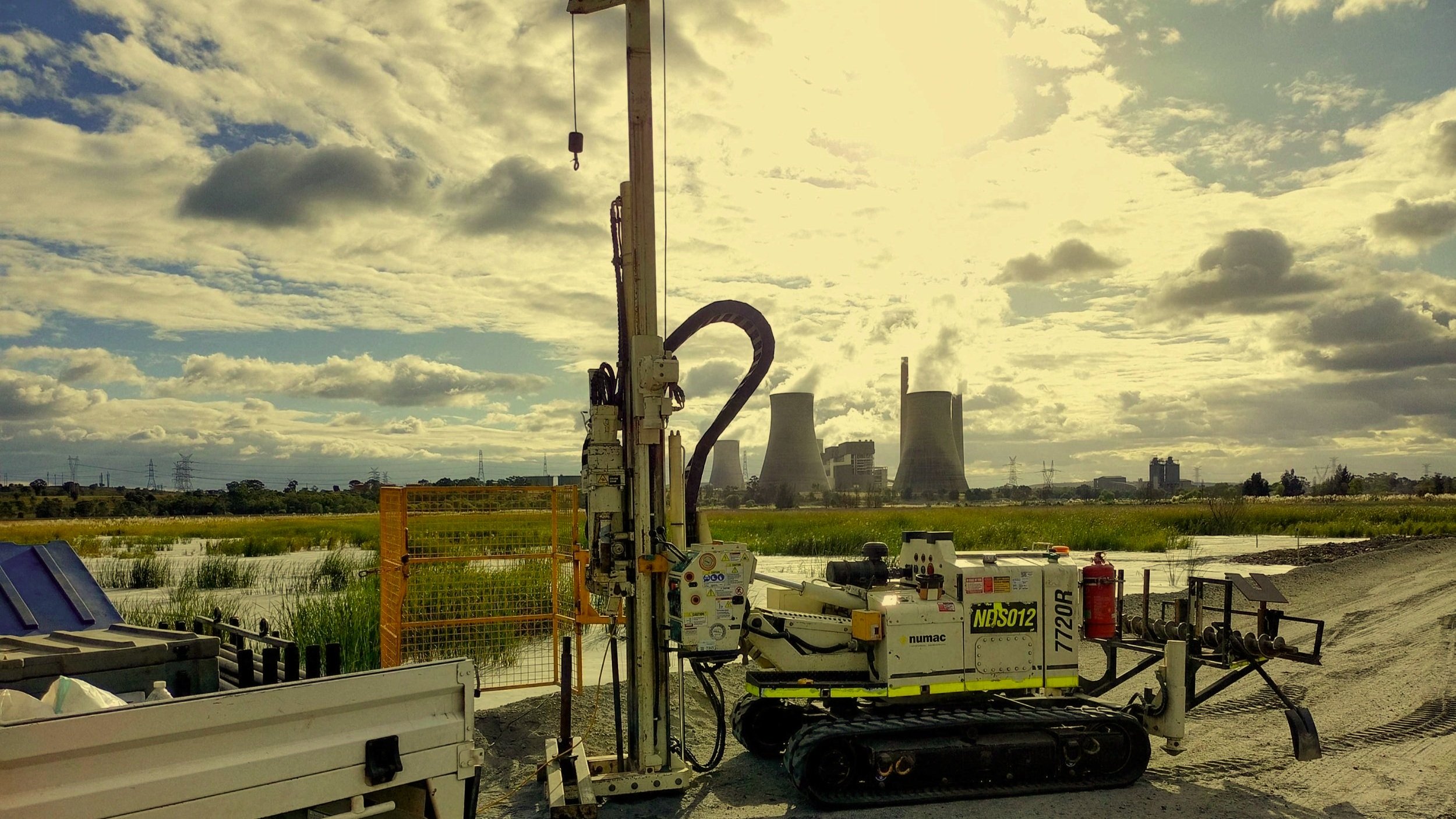

Electrical vane shear testing is mainly used to estimate undrained shear strength and remoulded (residual) shear strength. It is frequently employed along with other tools such CPT, CPTu, SCPTu and DMT.

The system mainly consists of a vane that is rotated through a software-controlled motor. Measurements with a high-precision torque sensor are used to derive shear strength values at depths of interest.

Geomil Electrical Shear Vane system for geotechnical testing of low strength soils.

Introduction to Electrical Vane Shear Testing

Electrical vane shear testing (VST) is a reliable method used to determine the undrained shear strength of cohesive soils. This test is particularly valuable for geotechnical engineering projects where an accurate understanding of soil stability is critical. By employing cutting-edge Geomil equipment, the process is streamlined, yielding precise and repeatable results that meet rigorous industry standards.

What Is Electrical Vane Shear Testing?

Electrical vane shear testing involves inserting a vane into the soil and rotating it to measure the torque required to shear the soil. This provides an accurate measure of the soil’s undrained shear strength, which is crucial for applications such as foundation design, slope stability assessments, and determining safe bearing capacities. The test is ideal for cohesive soils like clays and silts, where understanding shear strength is key to ensuring project safety and longevity.

With advancements in technology, traditional manual methods have largely been replaced by electrical systems such as those developed by Geomil. These systems enable real-time data collection, enhanced precision, and efficiency in various site conditions.

Why Choose Geomil Equipment for Vane Shear Testing?

Geomil is a trusted name in geotechnical engineering, known for its innovative and robust testing solutions. The Geomil electrical vane shear testing equipment offers numerous advantages, including:

High Accuracy: Geomil equipment ensures precise measurements of torque and rotation, resulting in accurate calculations of undrained shear strength.

Real-Time Data Collection: Integrated data acquisition systems allow for real-time monitoring and analysis, reducing errors and saving time.

Portability: Compact and lightweight designs make Geomil equipment easy to transport and set up, even in challenging site conditions.

Durability: Built with high-quality materials, the equipment is designed to withstand the rigors of fieldwork while maintaining performance.

Compliance: Geomil VST systems adhere to international standards such as ASTM D2573, ensuring consistent and reliable results.

Applications of Electrical Vane Shear Testing

Electrical vane shear testing is utilized in a wide range of geotechnical applications, including:

Foundation Design: Determining the undrained shear strength of cohesive soils is essential for designing stable foundations for buildings, bridges, and other infrastructure.

Slope Stability: Engineers use VST data to analyze and mitigate the risk of slope failures, particularly in landslide-prone areas.

Soil Improvement Projects: VST helps assess the effectiveness of soil stabilization techniques such as preloading, vertical drains, or chemical stabilization.

Pipeline and Offshore Projects: In marine environments, understanding the shear strength of sediments is crucial for the installation of pipelines, anchors, and offshore structures.

Earth Dams and Embankments: Accurate shear strength data is vital for the design and maintenance of earthen structures.

Key Features of Electrical Vane Shear Testing Equipment

Geomil’s electrical vane shear testing systems incorporate advanced features that set them apart in the field of geotechnical testing:

Digital Torque Measurement: The equipment uses state-of-the-art torque sensors to deliver accurate and reliable readings.

Rotational Control: Precise rotational mechanisms ensure consistent and repeatable results.

Integrated Software: Geomil systems come equipped with user-friendly software for data logging, analysis, and reporting.

Customizable Options: The equipment can be tailored to meet specific project requirements, offering flexibility for various soil types and testing depths.

Robust Construction: Designed for long-term use, Geomil systems are resistant to environmental challenges such as moisture, dust, and extreme temperatures.

Step-by-Step Process of Electrical Vane Shear Testing

Site Preparation: The testing area is cleared, and the equipment is set up according to site-specific conditions.

Insertion: The vane is inserted into the soil to the desired depth using a rod or drill rig.

Rotation: The vane is rotated at a controlled rate, and the torque required to shear the soil is recorded.

Data Analysis: Real-time data is processed using Geomil’s integrated software, providing accurate measurements of undrained shear strength.

Reporting: Comprehensive reports are generated, including graphs and data tables, to aid in decision-making for geotechnical projects.

Advantages of Electrical Vane Shear Testing Over Traditional Methods

Electrical vane shear testing offers several benefits over manual or analog methods:

Enhanced Precision: Digital systems reduce human error and provide more reliable results.

Time Efficiency: Automated data collection and analysis significantly speed up the testing process.

Repeatability: Consistent control over testing parameters ensures repeatable and comparable results.

Data Storage: Electronic systems enable easy storage and retrieval of test data for future reference.

Versatility: Electrical systems can be adapted to various site conditions, including both onshore and offshore environments.

Best Practices for Electrical Vane Shear Testing

To achieve optimal results, it’s essential to follow best practices when conducting electrical vane shear testing:

Calibrate Equipment Regularly: Ensure that all sensors and components are calibrated before each use to maintain accuracy.

Choose the Right Vane Size: Selecting an appropriate vane size based on soil type and strength is critical for accurate measurements.

Control Insertion and Rotation Rates: Consistent rates are essential to avoid disturbing the soil structure.

Document Site Conditions: Record details such as soil type, moisture content, and testing depth for comprehensive data analysis.

Train Operators: Proper training ensures that personnel can operate the equipment effectively and interpret results accurately.

Conclusion

Electrical vane shear testing with Legion Drilling represents the gold standard in geotechnical soil strength analysis. Combining precision, efficiency, and versatility, this advanced technology delivers reliable data for a wide range of applications. Whether for foundation design, slope stability assessments, or marine projects, Geomil’s VST systems provide the accuracy and dependability that engineers and contractors need to ensure project success. Contact us today to learn more about our electrical vane shear testing solutions and how they can benefit your geotechnical projects.