Pre-Packed Monitoring Wells

FAST EFFICIENT INSTALLATION OF MONITORING WELLS

Pre-packed wells represent an alternative to conventional monitoring systems in unconsolidated and unstable formations. Compared to conventional methods, the installation of pre-packed wells is considerably quicker, simpler, and produces minimal investigation-derived waste (IDW). These advantages contribute to build sound conceptual site models (CSMs) in contaminated sites.

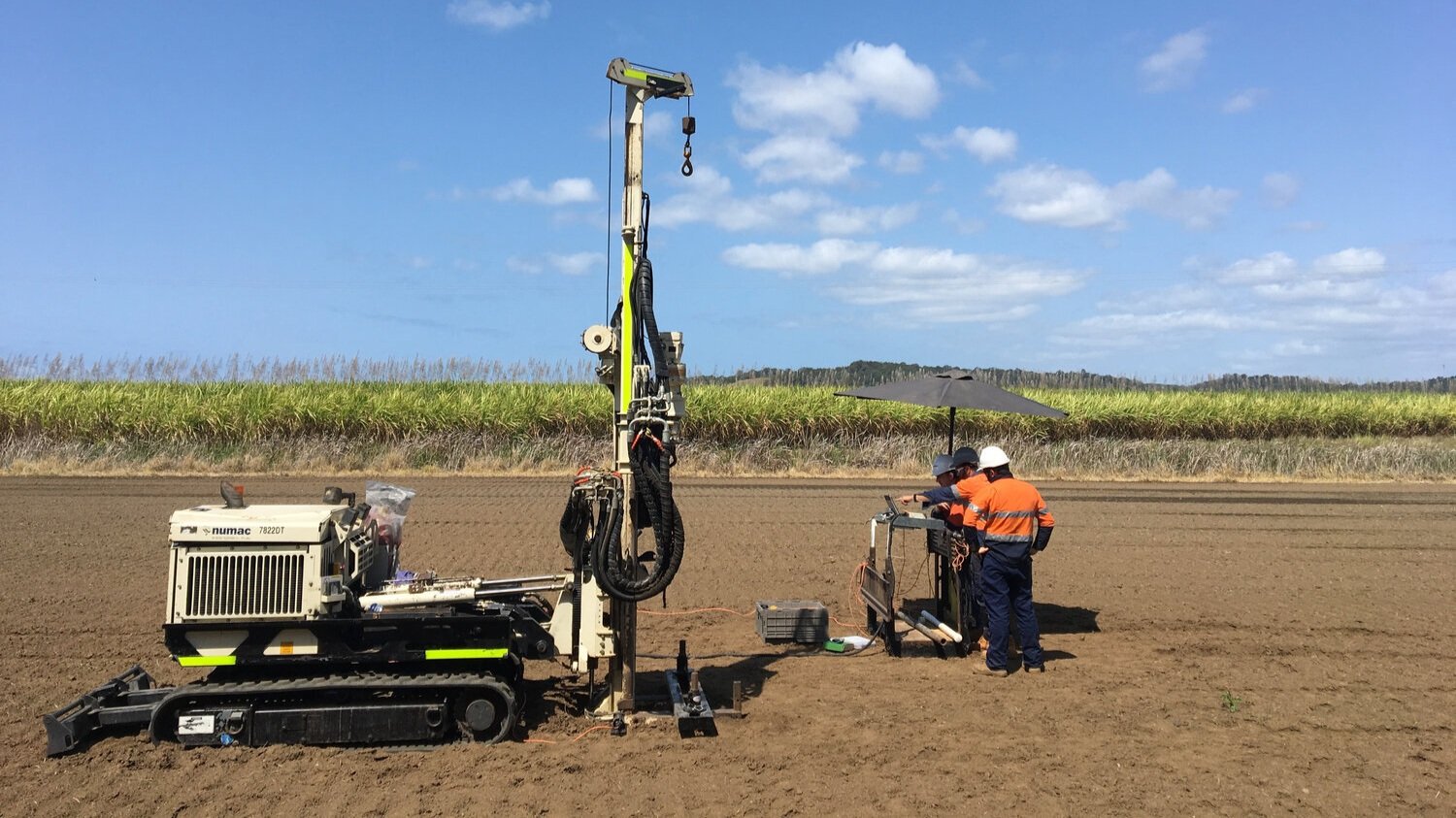

Pre-packed wells are installed with direct push technology. After advancing the rods into the subsurface to the desired depth, the well assembly is installed and the rods are retracted. Subsequently, the well can be grouted (a sand barrier prevents grout from entering the screen), developed, purged, and sampled. Well development produces lower amounts of water and is faster than in the case of conventional monitoring wells.

What Is a Pre-Packed Screen?

A pre-packed screen is a specialized well screen used in groundwater monitoring, dewatering, or environmental sampling. It consists of a perforated or slotted inner pipe surrounded by a uniform layer of filter material, typically sand or gravel, which is encased within a protective outer mesh or jacket. This design simplifies the installation process by combining the well screen and filter pack into a single unit.

Key Features of Pre-Packed Screens:

Integrated Filter Pack

The pre-packed layer acts as a filter to prevent fine particles, such as sand or silt, from entering the well, ensuring clean and accurate water samples. This eliminates the need for a separately installed filter pack during well construction.Ease of Installation

Pre-packed screens simplify installation by reducing the number of steps and materials required. They are particularly useful in narrow-diameter boreholes or sites with limited access.Consistent Packing

The filter media in pre-packed screens is uniformly graded and packed to ensure even permeability and prevent gaps or voids, which can occur during manual filter pack installations. This is particularly true of hollow aguer installations which are challenging and diffucult to maintain consistency.Applications

Pre-packed screens are commonly used in groundwater monitoring wells, landfill leachate recovery systems, and environmental remediation projects. They are also valuable in areas with unstable or fine-grained soils where achieving effective packing is challenging.Minimal investigation-derived waste (IDW). When installed using a direct push method with a Geoprobe rig there is no waste generated during the installation.

By streamlining well construction, reducing clogging risks, and ensuring consistent filtration, pre-packed screens are an efficient and reliable solution for various subsurface monitoring and sampling applications.

Potential Issues with Pre-Packed Screens

While pre-packed screens offer several advantages, they may not be suitable for all applications. Here are some common issues or limitations associated with pre-packed screens:

Limited Customization

The filter pack is pre-installed and pre-graded, which means the grain size may not match the exact gradation of the surrounding soil. This can lead to suboptimal performance in certain geological conditions, especially if the surrounding formation contains particles that are smaller than the filter media.Clogging Risks

If the pre-packed filter media is not appropriately selected for the site conditions, fines from the formation can penetrate and clog the filter pack, reducing its efficiency and lifespan.Restricted Filter Pack Thickness

The thickness of the pre-packed filter layer is fixed, which might not be sufficient for formations with highly unstable or fine-grained soils. In such cases, a custom-installed filter pack may perform better.Higher Cost (possibly)

Pre-packed screens are typically more expensive upfront than traditional well screens to purchase, although the installation time is faster. While they save time during installation, the added material and manufacturing costs can make them less economical on some projects. Each drilling project should be assessed to determine if the cost of pre-pack screens can be justified.Limited Diameter Options

Pre-packed screens are often available in a narrower range of diameters than conventional well screens, potentially limiting their use in larger boreholes or projects requiring specific dimensions.Durability Concerns

In some cases, the outer mesh or jacket of the pre-packed screen may not withstand extreme pressure or harsh environmental conditions, leading to deformation or damage during installation or operation.

Conclusion

While pre-packed screens simplify installation and provide consistent filtration, careful evaluation of site-specific conditions (such as soil gradation, hydrogeology, and borehole size) is crucial. In cases where custom filter pack specifications or highly unstable formations are involved, a traditional well screen with a manually installed filter pack may be more effective.

Further information on Pre-packed Screens.

Our technical specialists will be happy to provide further information and discuss in detail any specific project requirements.

In the meantime, we recommend you to consult the following documents:

ESTCP (2009). Demonstration/Validation of Long-Term Monitoring Using Wells Installed by Direct Push Technologies and Enhanced Low-Flow Groundwater Sampling Methods. ER-0011. Arlington, USA: Environmental Security Technology Certification Program. https://www.serdp-estcp.org/Program-Areas/Environmental-Restoration/Contaminated-Groundwater/Monitoring/ER-200011

Geoprobe (2020). Testing the Geoprobe® Prepacked Well Screens for PFAS Contamination. Geoprobe Technical Bulletin No. 2020DI04. https://geoprobe.com/sites/default/files/storage/pdfs/Prepack%20PFAS%20Tech%20Bul%202020DI04.pdf

ITRC (2008). An Overview of Direct-Push Well Technology for Long-term Groundwater Monitoring. Washington, D.C., USA: Interstate Technology & Regulatory Council, SCM Team. https://clu-in.org/conf/itrc/directpush_121108

McCall, W., & Christy, T. (2018). Direct Push Sampling. Enviro Wiki. https://www.enviro.wiki/index.php?title=Direct_Push_Sampling&oldid=11358